A Successful RTK UAV Mapping Project with DJI Phantom 4 RTK and SinoGNSS T300 Plus

1. Project Overview

A rural residential area in Shanghai covering 250000m² (as shown in Fig.1) needs to be measured and mapped to obtain a high-accurate map. Featuring large area, time pressured and inadequate staffing, using traditional surveying methods is challenging to complete the project.Thus, an excellent solution combining of Phantom 4 RTK (hereinafter referred to as P4R) and T300 Plus GNSS receiver is proposed with no image control points, short-time field work and labor-saving.

Fig. 1 Site Environment

2. Challenges

The rural environment is covered with poor 4G network as normally base stations and UAVs transmit correction streams via 4G.

No image control points will reduce the workload but cause no accuracy validation.

Project operators are faced up with technical challenges as the new land surveying method is different from the traditional one largely.

3. Benefit

Less Workload: Compared with traditional UAV mapping, RTK drone mapping depends less on control points as it is high-precision, which will reduce the workload in a large extent.

WIFI Connection: Equipped with WIFI module, T300 Plus can transmit data easily, free from the restriction of Internet.

Accuracy Validation: Except for being a base station, T300 Plus can also work as a rover to measure the coordinates of check points for accuracy validation.

Easy to Use: Easy configuration and simple workflow, no threshold for users.

PPK Backup: To prevent situations where RTK is not applicable, T300 Plus also provides PPK as a backup plan, which can be performed simultaneously with RTK.

4. Project Summary

4.1 Date

Field work was completed on 10/26/2020, office work was conducted from 10/26/2020 to 10/27/2020.

4.2 Location

Beixin Village, Jiading District, Shanghai, China

4.3 Instruments

1 × DJI Phantom 4 RTK

1 × T300 Plus GNSS Receiver

5 × checkmarks

4.4 Software

Survey Master

Pix4Dmapper

4.5 Procedure

4.5.1 Set up Check Points

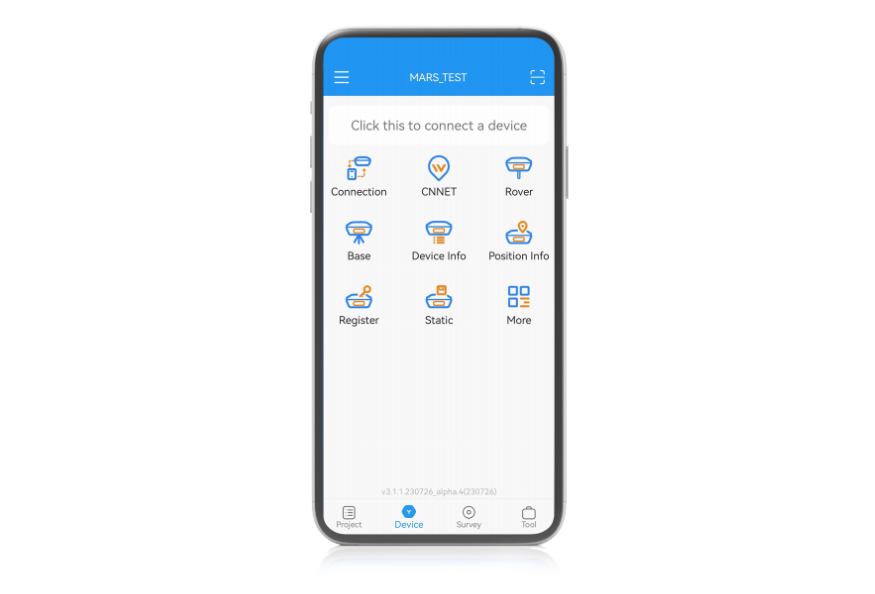

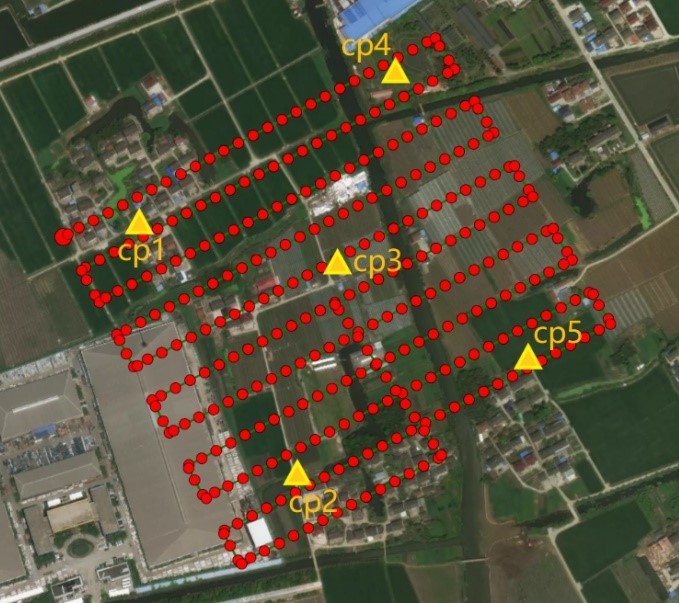

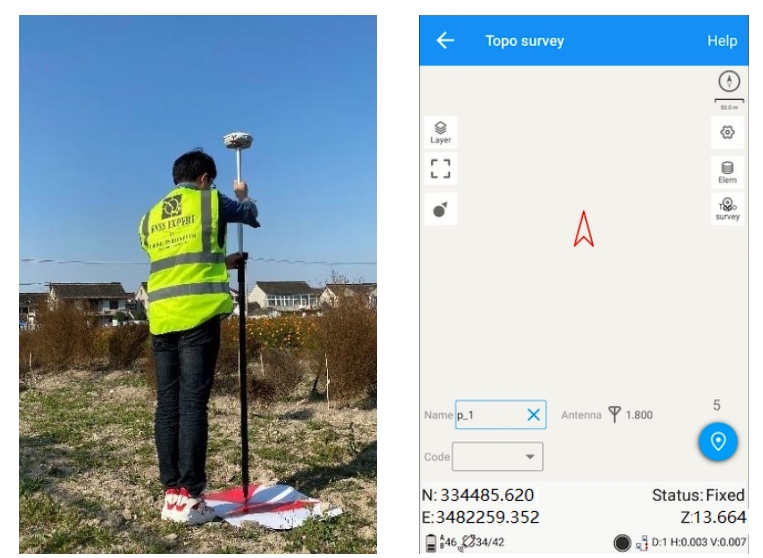

5 check points were placed over the mapping area uniformly, which’s distribution was shown in Fig. 2. The coordinates were surveyed by SinoGNSS® T300 Plus receiver via Survey Master software in PDA CORS Mode. Survey Master improves the convenience and reliability of this measuring project as its strong functionality and simplified work flow. With no need of a controller, it can be easily downloaded from Google Play Store and installed on an Android-based smart phone.

Fig. 2 Check Points Distribution Marked in Yellow

Fig. 3 Check Point Measurement (L) and Survey Master Interface (R)

The check points were only used for accuracy validation without participating in the data processing, causing no influence on the final result.

4.5.2 Set up Base Station

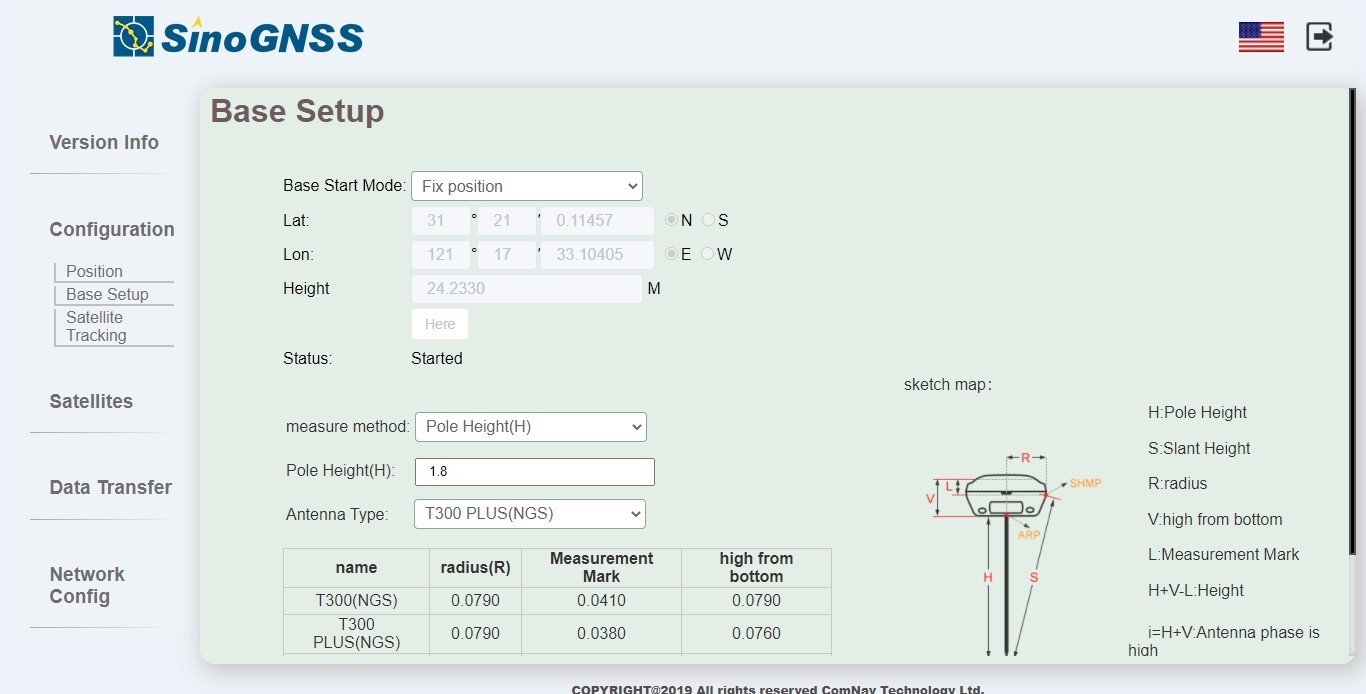

On the control point (known point) of mapping area, T300 Plus was set up as base station to transmit correction data to P4R, connected to P4R via WIFI link. Benefit from the web UI of T300 Plus (shown in Fig. 5), it is easy to configure the known point coordinates and related settings on P4R remote controller.

Fig. 4 Base Station

Fig. 5 Web UI of T300 Plus

4.5.3 UAV Configuration

The flight route and relevant settings were configured on the remote controller before flying, which are given in Tab 1 and Fig. 6, respectively. It took only 13min for UAV mapping to collect a total of 333 images data in the large site area of 250000m2. When shooting each image, the coordinates of the CMOS were surveyed via the RTK module and attached to each image data.

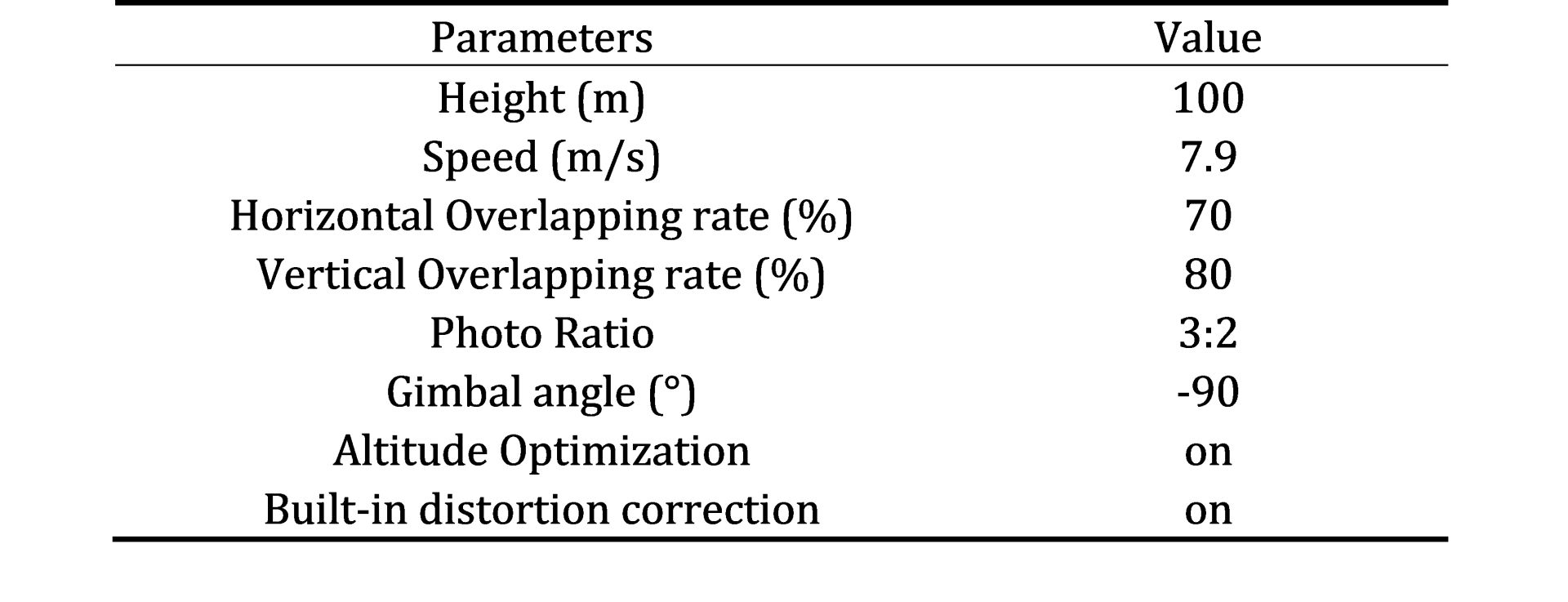

Tab 1: Flight Parameters

Fig. 6 Flight Route

4.5.4 Data Processing

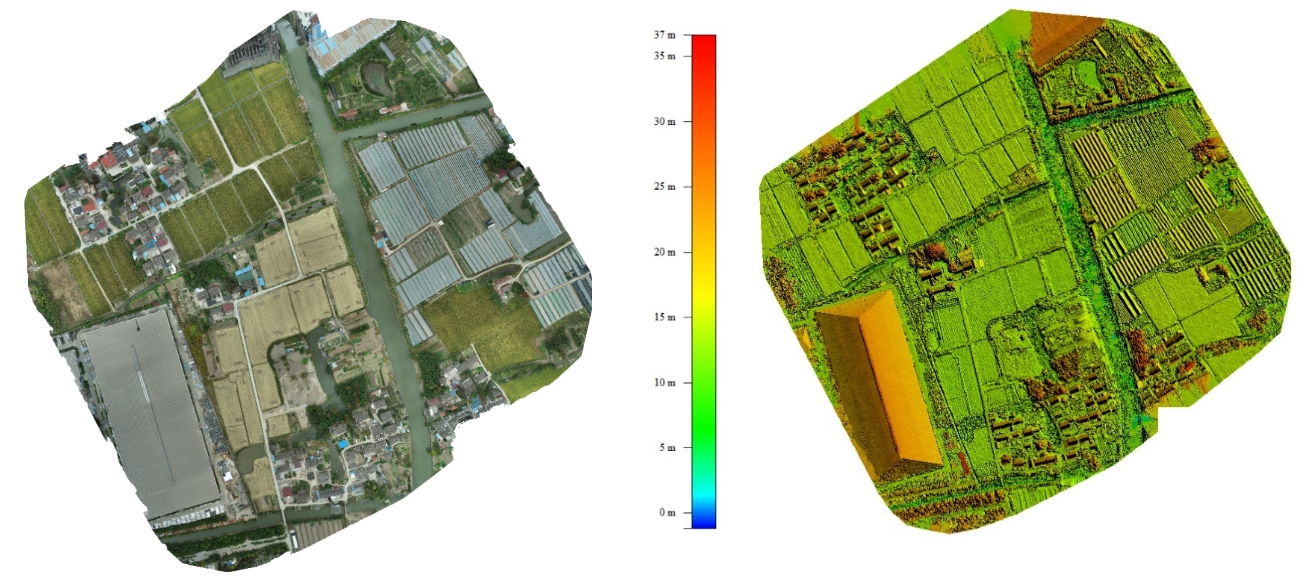

After input of the P4R images into Pix4Dmapper, related processes automatically ran, including initialization, images stitching, distortion correction and etc., and finally the DOM (Digital Orthophoto Map) and DSM (Digital Surface Model) results were generated, as shown in Fig. 7 and Fig. 8. The GSD (average ground sampling distance) is 2.95cm.

Fig. 7 DOM Result (L) Fig. 8 DSM Result (R)

4.5.5 Accuracy Validation

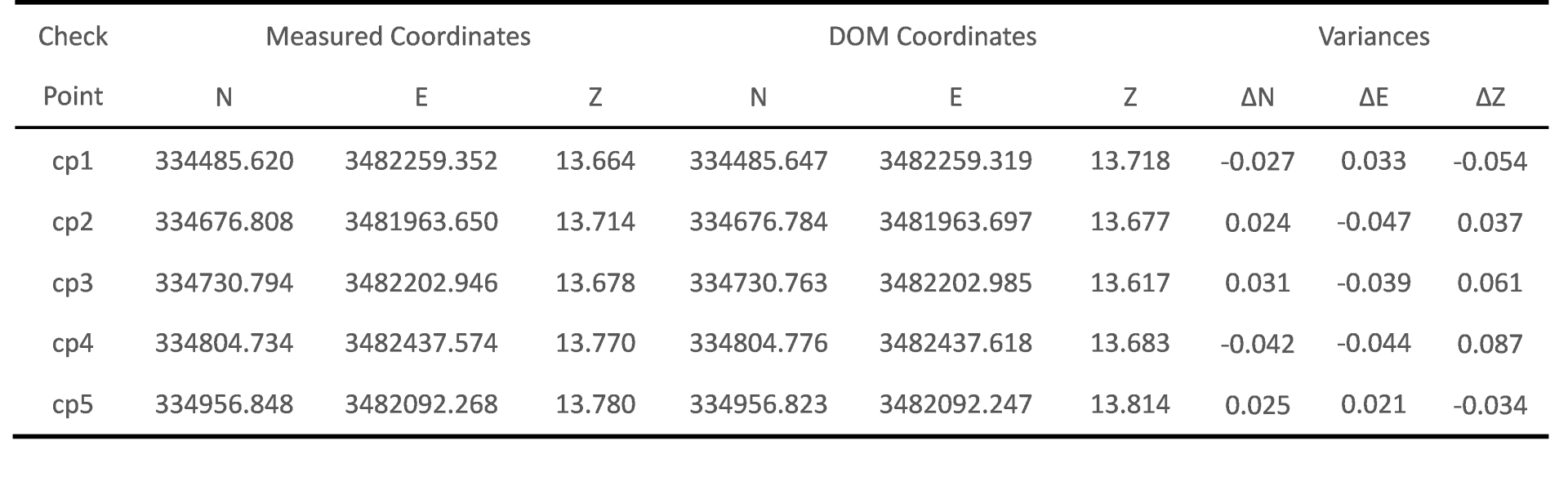

Based on the measured check points, the variances between the DOM coordinates and the measured coordinates were calculated to validate the accuracy. They are within 10cm vertically and 5cm horizontally, as illustrated in Tab 2 below.

Tab 2: Check Points Accuracy

5. Conclusion

In conclusion, compared with traditional UAV mapping or land surveying, the RTK drone mapping with P4R manifested higher efficiency, simpler workflow and less workload. which can save both time and labor, turning a large proportion of field work into office work. The mapping solution combining a continuous and reliable T300 Plus base station with a commercial UAV rover of Phantom 4 RTK can provide centimeter-level mapping precision to meet most surveying work demands. Thus, it is both high-accuracy and cost-efficient.

As an indispensable part of this mapping solution, T300 Plus receiver played role as a powerful backup. Supporting WIFI connection enables stable correction streams transmission. Its built-in web UI makes configuration easily. PPK backup plan reduces the absolute reliance on RTK. High-accuracy rover survey realizes accuracy validation of UAV mapping. It can be said as the best-in-class base station choice of drone mapping.

More information about the case study please refer to link below.

https://cetest02.cn-bj.ufileos.com/fsite_1802020370/DJI_CaseStudy.pdf

About ComNav Technology

ComNav Technology develops and manufactures GNSS OEM boards and receivers for high precision positioning demanded applications. Its technology already been used in a wide range of applications such as surveying, construction, machine control, agriculture, intelligent transportation, precise timing, deformation monitoring, unmanned system. With a team dedicated for the GNSS technology, ComNav Technology is trying its best to supply reliable and competitive products to worldwide customers. ComNav Technology has been listed on the Shanghai Stock Exchange (Science and Technology Board), securities :ComNav Technology (Compass Navigation), Stock code: 688592.

About SinoGNSS®

SinoGNSS® is the official trademark of ComNav Technology Ltd., registered in People's Republic of China, EU, USA and Canada. All other trademarks are the property of their respective owners.

About ComNav Technology

ComNav Technology develops and manufactures GNSS OEM boards and receivers for high precision positioning demanded applications. Its technology already been used in a wide range of applications such as surveying, construction, machine control, agriculture, intelligent transportation, precise timing, deformation monitoring, unmanned system. With a team dedicated for the GNSS technology, ComNav Technology is trying its best to supply reliable and competitive products to worldwide customers. ComNav Technology has been listed on the Shanghai Stock Exchange (Science and Technology Board), securities :ComNav Technology (Compass Navigation), Stock code: 688592.

About SinoGNSS®

SinoGNSS® is the official trademark of ComNav Technology Ltd., registered in People's Republic of China, EU, USA and Canada. All other trademarks are the property of their respective owners.